Test Benches

Our Test Benches at a Glance

Freudenberg Sealing Technologies offers numerous test benches worldwide that are specially tailored to different product groups.

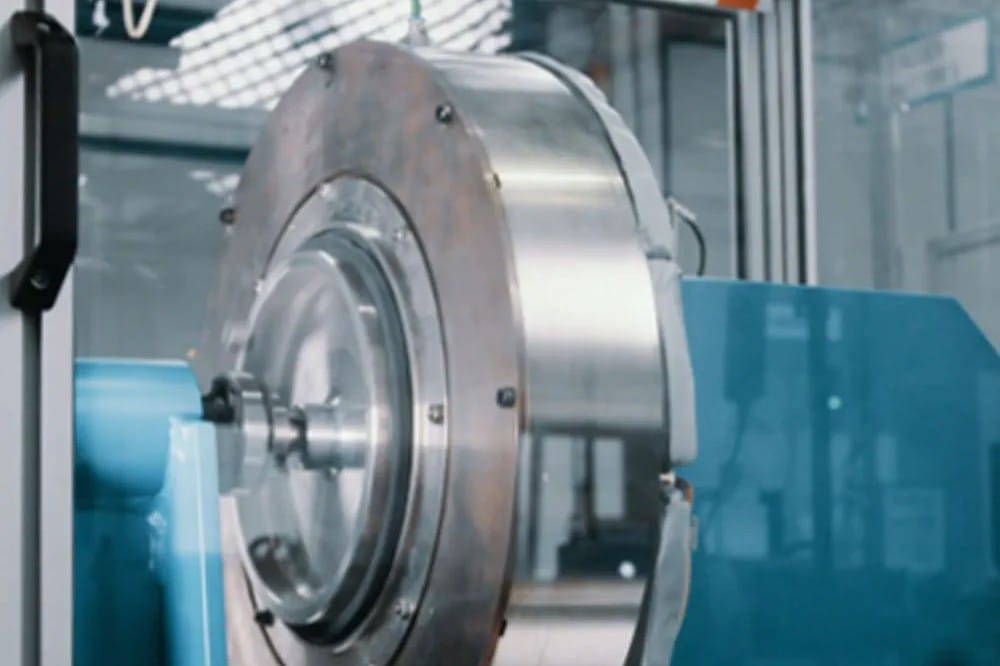

Test Benches for Rotation Application and Oil Seals (Simmerring®)

Our specific test rigs for oil seals applications are equipped for tests of pressure, temperature, friction torque and speed as well as changes in mechanical properties, characterization of tribological system interactions, leak detection and failure analysis.

Your Benefits at a Glance

-

Sealing materials and designs can be harmonized with lubricants

-

Seal designs can be validated to DIN / ISO or individual specification

-

Validation of your lifetime expectation

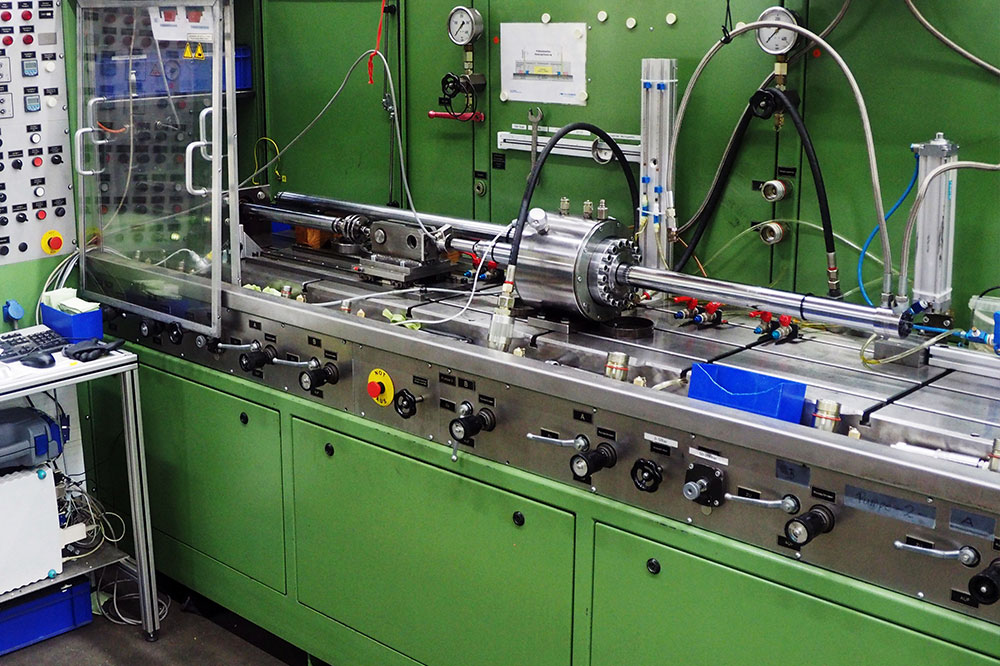

Test Benches for Cylinder Application and Hydraulic and Pneumatic Sealing Systems

For validation of hydraulic sealing systems, we provide test rigs that enables customer-specific tests as lifetime tests for hydraulic and pneumatic sealing systems in combination with lubricants. Next to friction and assembly tests, high- and low-temperature tests to identify the best component for individual processes.

Your Benefits at a Glance

-

Validation of best in class Sealing system according to your requirements

-

Validate lifetime requirements under real condition

-

Validate Sealing System to Lubricant combination

Testing possibilities for accumulators, components and hydraulic systems

We have all the necessary test equipment to test hydraulic components and systems according to customer-specific requirements.

Our Testing Offering at a Glance:

-

Dynamic housing swell strength

-

Static burst pressure

-

Life cycle e.g. pressure – and temperature profiles

-

Corrosion test e.g. salt spray test, constant climate test, change climate test

-

System and component testing

CIP/SIP Test Bench for the Process Industry

Seals can be tested in your customer-specific media, in all common CIP/SIP media and in steam and hot water sterilization. All types of elastomeric seals in valves and aggregates, such as O‑rings, diaphragms and molded parts can be integrated and tested. This enables you to check your seal design or optimize it before production begins and reduces amount of field tests.

Your Possibilities at a Glance:

-

Testing of all types of elastomeric seals in valves and aggregates such as O-rings, diaphragms, butterfly valve and profile seals and molded parts

-

Testing of metrology and pump seals

-

Sealing tests in connection with alkalis, acids and disinfectants

-

Testing of critical applications with steam, cold and hot product media

-

Performance of damage analyses for existing sealing problems

Do You Have Questions About Test Benches?

Our experts will be happy to answer your questions personally.

Write us your request and we will call you back.