Power Generation

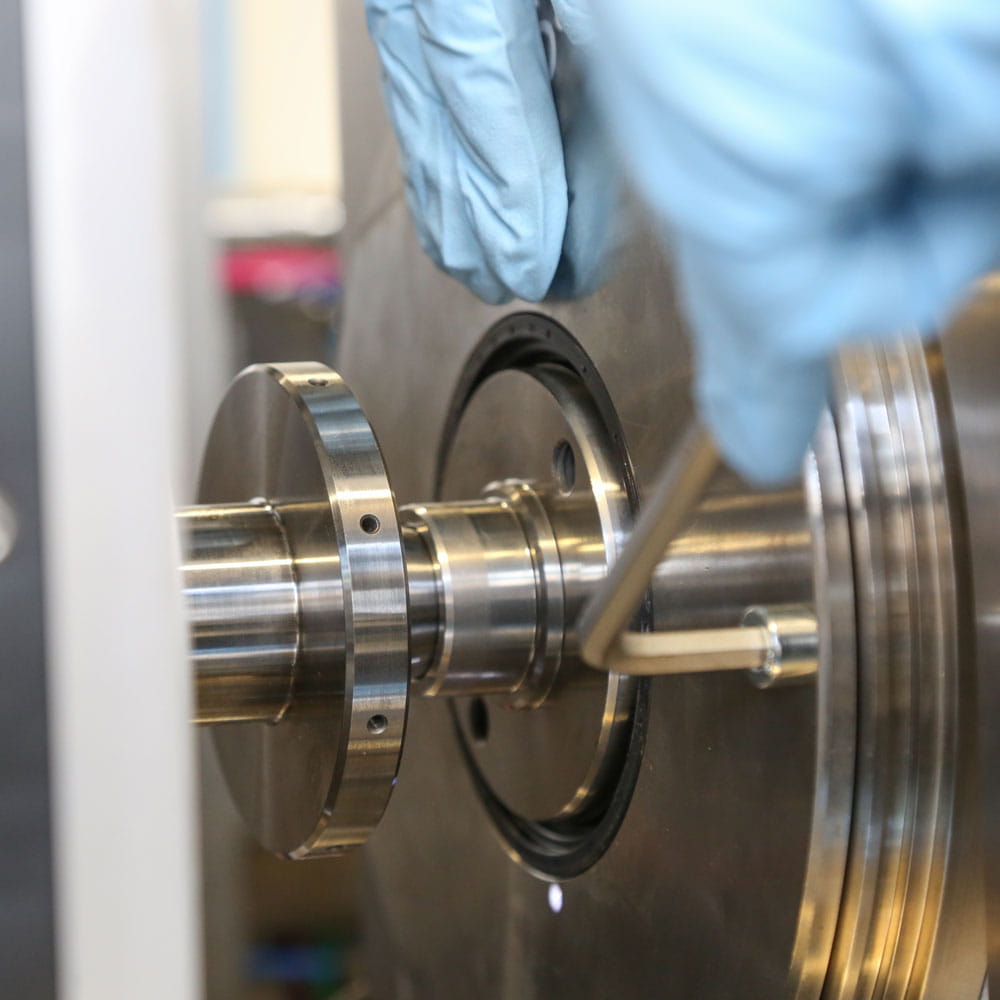

Fluid Supply Seals

Sealing Solutions for Power Generation

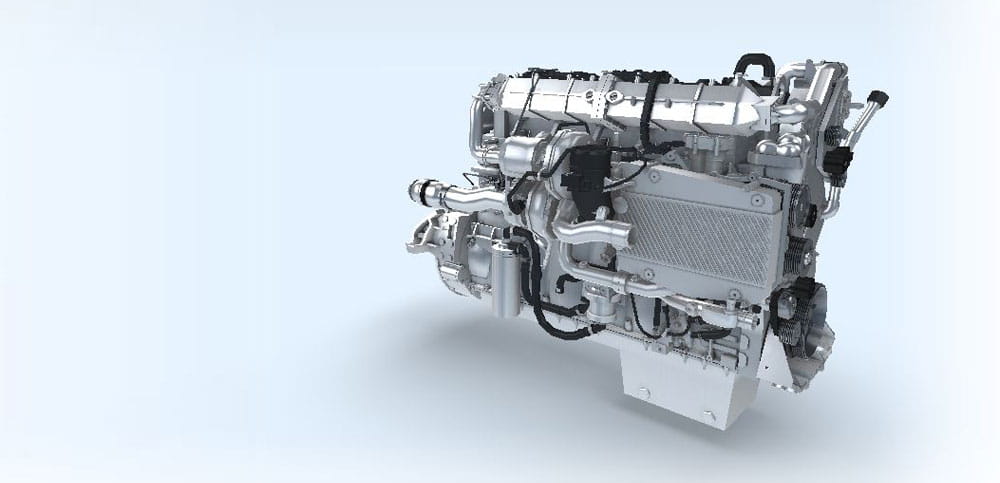

Whether in mining, ships, agricultural or construction machinery, whether in stationary or mobile applications: Combustion engines are the pacemakers of industrial production. They have paved the way for progress and economic growth for generations. Large diesel engines must run reliably and economically even under the most adverse operating conditions. At the same time, they have to comply with increasingly stringent emission regulations. Wherever you look, diesel and gasoline engines also drive our everyday and leisure activities: in scooters and cars as well as in lawn mowers and chainsaws.

Static and dynamic seals from Freudenberg Sealing Technologies – starting with the original Simmerring® – ensure leakage-free functional reliability at all times. Rarely visible, but indispensable, our sealing technology helps wheels rotate and interlock in almost all life situations: low-friction, low-emission, technically and economically efficient and environmentally friendly at the same time.

New Drive Expertise

In the future, electric motors with several tens of thousands of revolutions per minute will be increasingly used to specify new cycle rates. As a result, the requirements in the drive train in terms of temperature and pressure load are growing. These requirements can no longer be met with conventional seals and materials. Thanks to our innovative strength resulting from our materials, technology and process expertise, our pipeline is already filled with a wealth of new sealing concepts and products for the electric drives of the future.

Engineering Services

The Simmerring® test facility at the company’s headquarters in Weinheim, Germany, with more than 230 test benches for combustion engines and electric motors is only part of the systematic development work and quality assurance at Freudenberg Sealing Technologies. Manufacturers of additives for engine and transmission oils use this unique facility to test the compatibility of their chemical additives with sealing elastomers. In addition to dynamic resistance and leak testing, Freudenberg Sealing Technologies offers a wide range of other sophisticated engineering services. These include damage, shaft and bore analyses, installation studies, benchmark tests, finite element analyses and much more.

How can we help you?

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn!