Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

Rod Seals

Hydraulic Cylinder Rod Seals & Pneumatic Rod Seals

Rod Seals From Freudenberg Sealing Technologies Perform Multiple Tasks

Rod Seals are primarily used in pneumatic and hydraulic cylinders and have the task of sealing the incoming and outgoing cylinder rod. The goal is to prevent the escape of the pressurized operating medium from the cylinder. At the same time, it must be protected against external contaminants. Freudenberg Sealing Technologies offers the right Rod Seal for every kind of cylinder and application.

Maximum Efficiency From the Best Possible Combination

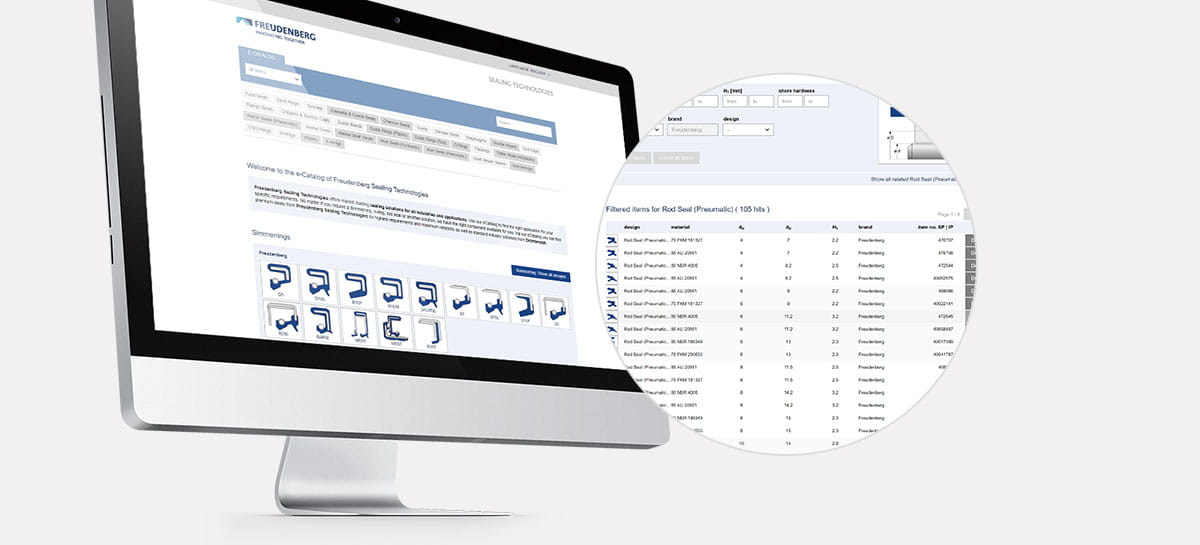

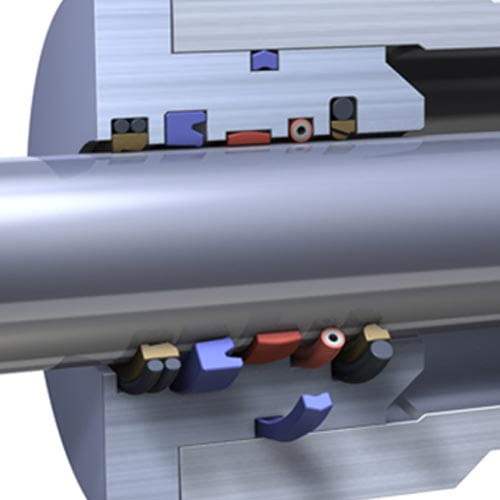

Rod Seals from Freudenberg Sealing Technologies are used in state-of-the-art sealing systems for cylinders of all kinds. They are specially adapted to the respective conditions of use and tasks while meeting customers’ high expectations for maximum reliability, service life and functionality. State-of-the-art hydraulic rod sealing systems generally consist of several individual seals (see example in Fig. 1). The so-called primary seal faces the cylinder’s working space and reliably seals against the high operating pressure within the cylinder.

The secondary Rod Seal fitted behind it takes over the main sealing function. It is above all designed to reduce the residual oil film on the rod to a minimum during its extension. Seals constructed of polyurethane are preferably used for this task. With their defined sealing lip, they ensure the finely tuned wiping of the medium, guaranteeing the leak tightness of the cylinder toward the exterior.

So-called wipers are used as a third element in the rod sealing system, in addition to the guide elements that prevent the contact of the incoming and outgoing rod with the housing. Their task is to protect the systems’s primary and secondary seals from external contamination and influences. In addition, Static Seals are needed for the cover/cylinder housing intersection.

Freudenberg Sealing Technologies has continued to develop its rod sealing systems and to equip them with additional functions. For example, in addition to storage modules to take in drag oil, pressure discharge functions are used when special requirements arise, including long strokes or great differences in a rod’s incoming and outgoing speed. They effectively prevent an excessive system-related buildup of pressure within the sealing system and protect against the premature failure of the primary and secondary seals.

State-of-the-art pneumatic rod sealing systems use combined wiping/sealing elements as their operating pressures are lower than those of hydraulic systems. In combination with special materials, these sealing systems are high-performing and an outstanding value for the money.

Whatever the conditions, sealing systems from Freudenberg Sealing Technologies stand for excellent long-term performance.

The sealing of piston rods poses challenges that are difficult to resolve. To reliably retain the hydraulic fluid, the seal material must be relatively soft and resistant to abrasion, while at the same time, the material must have the hardness needed to prevent gap extrusion at high operating pressures and temperatures. Freudenberg Sealing Technologies combines these contradictory requirement profiles in a single component, the HDR-2C.

This rod seal consists of two high-performance polyurethane compounds with different hardnesses, which Freudenberg chemically combines into a single seal. This removes the need for a back ring and so facilitates easier installation.

The HDR-2C is thus the ideal solution for harsh operating conditions. It stays dynamically sealed under low and high pressure loads in a broad range of temperatures, from -50 to + 110°C. When compared to conventional one-component rod seals, extrusion gaps that are twice the normal allowable size are possible.

- The LF300 rod seal exhibits especially low friction in pressure applications with a range up to 160 bar.

- It is used for cylinder pressures of up to 320 bar and can withstand temperatures between -30°C and 110°C.

- A high degree of static and dynamic leak tightness is achieved due to its pierced seal edges.

- An asymmetric profile with a recessed interior lip is characteristic of its structure.

- The seal features a protected design with a grooved contact surface on its inner diameter, which enables jerk-free movement even at very low slide speeds.

- Along with its optimized stick-slip behavior, the product features an outstanding dynamic oil return feed.

- Its external diameter provides a tight, secure fit that is used as a primary and secondary seal in the rod seal systems at permissible slide speeds up to 0.6 m/sec (for primary seals) or 0.8 m/sec (for secondary seals).

- Highly wear-resistant polyurethane is used to create this amazing seal and it can be produced in a low temperature version that can withstand temperatures as low as -50°C.

- The T20 rod seal is available in standard sizes and is used for cylinder pressure up to 400 bar at temperatures between -30°C and 110°C

- This product can be delivered on short notice in dimensions between 8mm to 320mm.

- T20 seals have pierced edges that are used to achieve a high degree of static and dynamic leak tightness.

- The T20 is used as the primary seal for slide speeds up to 0.5m/sec.

- At speeds between 0.5 and 0.8m/sec, it functions superbly as a secondary seal in rod seal systems.

- The geometric design of the seal accommodates oil feedback into the pressure chamber.

- The T20 rod seal is manufactured using highly pressure-resistant polyurethane.

- Special versions, such as variations for a diameter range >320mm or low temperature applications as low as -50°C, are possible upon request.

- Given the totality of its positive characteristics, the T20 provides very good value for the cost.

Our Products in Detail

-

Merkel® Chevron Seal Set DMS-0180

-

Merkel® Chevron Seal Set ES61

-

Merkel® Chevron Seal Set ES81

-

Merkel® Chevron Seal Set ES/ESV

-

Merkel® Compact Seal S8

-

Merkel® U-ring 0214

-

Merkel® U-ring 0216

-

Merkel® U-ring 0503

-

Merkel® U-ring L20

-

Merkel® U-ring NRSF-8009

-

Merkel® U-ring T20

-

Merkel® U-ring TM20

-

Merkel® U-ring TM23

-

Merkel® U-ring TMP20

-

Merkel® Omegat OMS-DR HB

-

Merkel® Omegat OMS-MR

-

Merkel® Omegat OMS-MR PR

-

Merkel® Omegat OMS-S

-

Merkel® Omegat OMS-S PR

-

Merkel® Omegat OMS-S SR

-

Merkel® Omegat OMSU-MR PR

-

Merkel® Syprim SM

-

Merkel® V-Packing Set V1000

Merkel® Chevron Seal Set DMS-0180

Multi-piece rod seal, consisting of a polyethylene thrust ring, polyethylene sleeves and an elastomer back-up ring. Suited to harsh operating conditions and ceramic counter surfaces.

Merkel® Chevron Seal Set ES61

Multi-piece rod seal, consisting of a thrust ring made of a PTFE-bronze compound, fabric sleeves and a rubber-sprung backup ring. For harsh operating conditions and large seal gaps.

Merkel® Chevron Seal Set ES81

Multi-piece rod seal made of a rilled thrust ring made of polyurethane, fabric sleeves and a rubber-sprung back-up ring. Suited to existing designs and short-term underpressure.

Merkel® Chevron Seal Set ES/ESV

Steering seals for rotational and reciprocating applications including hydraulic pump and valve seals and dust seals for electric steering systems.

Merkel® Compact Seal S8

Single-piece rod seal with an elastomer head set in the fabric part for light and medium requirements.

Merkel® U-ring 0214

Single-acting, two-piece rod seal suited for use in hydraulic and pneumatic applications. With fabric reinforcement on the running surface.

Merkel® U-ring 0216

Single-acting, two-piece rod seal suited for use in hydraulic and pneumatic applications. Shortened fabric reinforcement on the running surface.

Merkel® U-ring 0503

Two-piece rod seal with asymmetric polyurethane profile ring and back-up ring. Among other purposes, usable as a single seal in pressures up to 50 MPa and for bridging major seal gaps.

Merkel® U-ring L20

One-piece rod seal with asymmetrical elastomer U-ring and shortened interior lip. Preferably to be used as a secondary seal in a seal system with water and water emulsion operating media.

Merkel® U-ring NRSF-8009

Special single-acting U-ring for sealing severely soiled slewing bearings with a press-fit at the outer diameter. For pivoting motions or slow rotating movements at low to medium pressures.

Merkel® U-ring T20

Tried-and-tested, one-piece rod seal for use as secondary seal in a seal system or as a single seal in pressures up to 40 MPa, among other purposes.

Merkel® U-ring TM20

Turned version of the Merkel® T 20 rod seal with a press-fit at the outer diameter. Among other purposes, suited for use as a secondary seal in a sealing system or as a single seal for pressures up to 40 MPa.

Merkel® U-ring TM23

Two-piece rod seal with a polyurethane profile ring and a backup ring. Especially designed for the sealing of piston rods in rams, advancing cylinders, and secondary cylinders in progressive extension.

Merkel® U-ring TMP20

Single-acting rod seal made of abrasion-resistant polyurethane. For heavy-duty, pneumatic demands and high operating requirements.

Merkel® Omegat OMS-DR HB

Two-piece rod seal, consisting of a PTFE profile ring with retaining flange to secure against co-rotation and an O-ring as a pre-tensioning element. Suited for rotary and swivel movements.

Merkel® Omegat OMS-MR

Two-piece rod seal, consisting of a PTFE profile ring as well as an O-ring as a pre-tensioning element. Among other purposes, for use as the primary seal in a sealing system.

Merkel® Omegat OMS-MR PR

Two-piece rod seal, consisting of a PTFE profile ring with a pressure relief function as well as an O-ring as a pre-tensioning element. For use as the primary seal for long strokes or major speed differences in the incoming and outgoing rod.

Merkel® Omegat OMS-S

Two-piece rod seal, consisting of a PTFE profile ring and an elastomer profile ring as a pre-tensioning element. Especially for large diameters and heavy hydraulic applications.

Merkel® Omegat OMS-S PR

Two-piece rod seal, consisting of a PTFE profile ring with a pressure relief function and a support runner as well as an elastomer profile ring as a pre-tensioning element. For use in heavy hydraulic applications as a primary seal for long strokes and major speed differences in the incoming and outgoing rod.

Merkel® Omegat OMS-S SR

Two-piece rod seal, consisting of a profile ring made of PTFE or PE, a support runner, and an elastomer profile ring as a pre-tensioning element. Usable a single seal in combination with a double wiper. For short strokes up to 10 mm.

Merkel® Omegat OMSU-MR PR

Two-piece rod seal, consisting of a polyurethane profile ring with a pressure relief function and an O-ring as a pre-tensioning element. Usable as a single seal in combination with a double wiper.

Merkel® Syprim SM

Two-piece primary rod seal that is basically used within a seal system in combination with a U-ring (e.g. Merkel® U-ring T 20).

Merkel® V-Packing Set V1000

For the sealing of piston rods and plungers – in special cases for pistons as well. Thanks to its robust design, it is extremely well suited to highly demanding, heavy and even lying presses.

3D Animations

Discover our innovative sealing solutions for use in Hydraulic Applications

in the new 3D animations!

Related Documents

-

Merkel® Omegat OMS-MR

Merkel® Omegat OMS-MR is a two-piece seal set for sealing piston rods, consisting of a PTFE Profile ring and an O-ring as a prestressing element.

-

Merkel® Omegat OMS-S

Merkel® Omegat OMS-S is a two-piece seal set for sealing piston rods, consisting of a PTFE profile ring and an elastomer profile ring as a pre-stress element.

-

Merkel® V-Packing Set ES / ESV

Merkel® V-Packing Set ES or type ESV are multi-part seal sets for sealing piston rods, comprising one pressure ring, at least three V-rings and one support ring. The V-packing sets are available in three different versions.

-

Merkel® V-Packing Set V 1000

Merkel® V-packing Set V 1000 is used for sealing piston rods, plungers and, in exceptional cases, pistons in highly demanding heavy industry applications. Each set comprises of one pressure ring, three or four V-packing rings and one support ring. V 1000 sets are supplied either without back rings or with one or alternatively with two back rings at the support ring for enhanced extrusion resistance.

-

The Perfect Cylinder Program for Hydraulic Seals

The Freudenberg-NOK PERFECT CYLINDER program for hydraulic seals optimizes sealing technology to help customers reduce their costs and improve the performance of their machinery.

-

Merkel® V-Packing Set VPS40

Merkel® V-Packing Set VPS40 is a multi-part seal set for sealing piston rods, comprising one polyurethane pressure ring, one polyurethane V-ring and one elastomeric support ring as energizer.

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn!