Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

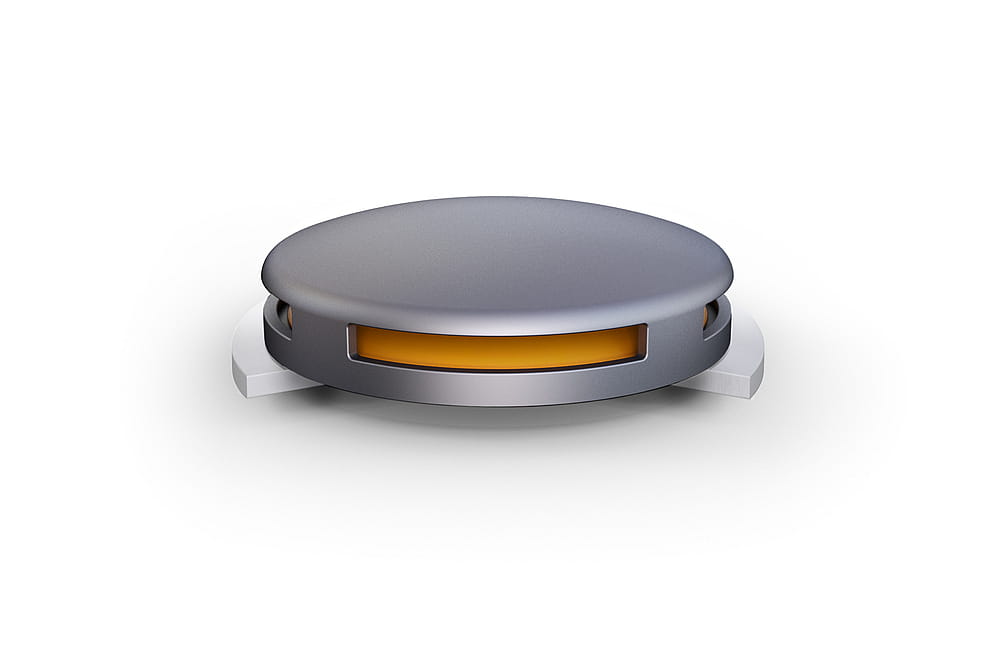

DIAvent®

DIAvent® – the Versatile Pressure Equalization Element for Lithium-Ion Batteries

Combined Pressure Equalization and Emergency Degassing in a Single Component

The hermetically sealed housings of lithium-ion batteries for vehicles must be equipped with special devices that perform the necessary pressure equalization.

The DIAvent® pressure equalization element combines several functions in a single component: pressure equalization during normal operation, fast and reliable opening for emergency degassing in a worst-case scenario – the thermal runaway of a cell – and subsequent closing after pressure equalization. The element thus ensures not only significantly greater safety, but is also more robust than conventional solutions.

All of the Benefits of Diavent® at a Glance:

- versatile functions in a single component

- small dimensions

- resealing increases safety after emergency degassing

- more robust than conventional solutions made of porous PTFE film

Our Products in Detail

DIAvent® Robust, Resealable, Safe

The patented DIAvent® pressure equalization element from Freudenberg consists of a centrally arranged 3-layer breathing element. The two outer water- and oil-repellent layers form a breathable, purpose-made laminate. They protect the inner layer from mechanical impact and contamination by dust particles.

The 3-layer coating offers greater robustness compared to the PTFE films commonly used in the past. Additionally, its performance exceeds conventional solutions in the market. This means that the pressure equalization element can be correspondingly smaller.

Emergency degassing takes place via an integrated shield valve that is arranged in a ring shape around the central breathing element. It is designed like a sealing lip and opens at pressure differences of around 40 mbar between the inside of the battery and the atmosphere. The valve closes again when the differential pressure drops. This prevents large quantities of ambient air from entering the battery and causing uncontrollable reactions. It also prevents further toxic products from contaminating the environment.

DIAvent® Highflow Greater Safety With Higher Energy Density

Freudenberg has developed the DIAvent® Highflow pressure equalization element specifically for battery systems with higher energy densities. The higher energy density also results in larger gas volumes that need to be dissipated quickly in case of an emergency.

DIAvent® Highflow is primarily designed for use in lithium-ion batteries in larger vehicles with very high energy densities and has four times the mass flow rate of the standard DIAvent® in case of an emergency.

To be able to achieve this in an emergency, the opening created by the sealing lip has not only been enlarged, but additional exhaust ducts have also been integrated.

DIAvent® Light Pressure Equalization in Normal Operation

DIAvent® Light is the ideal pressure management solution for the venting of dry-running electric motors and axles, inverters and battery systems. Consisting of a purpose-made, waterproof laminate, the element reliably handles the necessary bidirectional pressure equalization of the housings.

With its extremely high gas permeability, the pressure equalization element ensures reliable pressure equalization in normal operation even under demanding operating conditions in a wide temperature range.

The Challenge: Daily and in Case of an Emergency

The Daily Challenge: Pressure Fluctuations During Operation

Air pressure changes within the battery housing of a vehicle occur during normal driving operation. For example, when the vehicle drives over a mountain pass or the temperature in the battery housing changes in the period between a cold start and high speed on the highway. These pressure fluctuations are compensated for by an air exchange of several liters of air per minute in both directions. In the past, porous PTFE foils were usually used as a pressure equalization element for this purpose. The disadvantages of these solutions are essentially the high sensitivity with regard to mechanical influences as well as contamination by particles and liquid media, which ultimately reduce the air permeability. Here, DIAvent® & DIAvent® Highflow offers a practical alternative.

The Challenge in Case of an Emergency: Equalizing Pressure in Seconds

Foreign bodies in the cell, internal and external short circuits, defective overcharging or the destruction of the battery cell in an accident result in the release of high amounts of energy and gas volumes. The resulting gas then flows directly into the battery housing.

To reduce the resulting pressure as quickly as possible, battery housings usually have built-in rupture discs as predetermined breaking points to release the gas quickly in a controlled manner. Although these prevent the housing from being damaged, the destroyed disc leaves an opening to the outside after emergency degassing. This has significant disadvantages. Ambient air can be drawn into the battery after pressure equalization to create a combustible gas-air mixture that can cause further exothermic reactions inside the hot battery housing.

DIAvent® – the Safe and Reliable Solution

The DIAvent® & DIAvent® Highflow pressure equalization elements are not only extremely robust against mechanical stress, but also immediately closes the diaphragm that is opened in the event of emergency degassing. On the one hand, environmental pollution is prevented. On the other hand, it increases safety for anyone in the immediate vicinity of the vehicle – especially during the transportation of the damaged and fire dormant battery system.

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn!