Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

HNBR

HNBR O Rings Material- Hydrogenated Nitrile Rubber

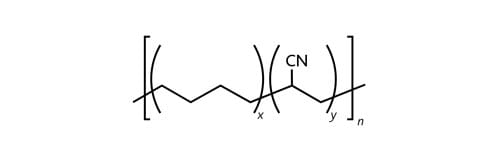

HNBR is produced through the selective hydrogenation1,2 of NBR. The reactive double bonds are removed from NBR. As a result, the molecule chain does not react as easily to oxygen and is thus significantly more heat resistant than NBR. In addition, HNBR offers better wear behavior in dynamic applications.

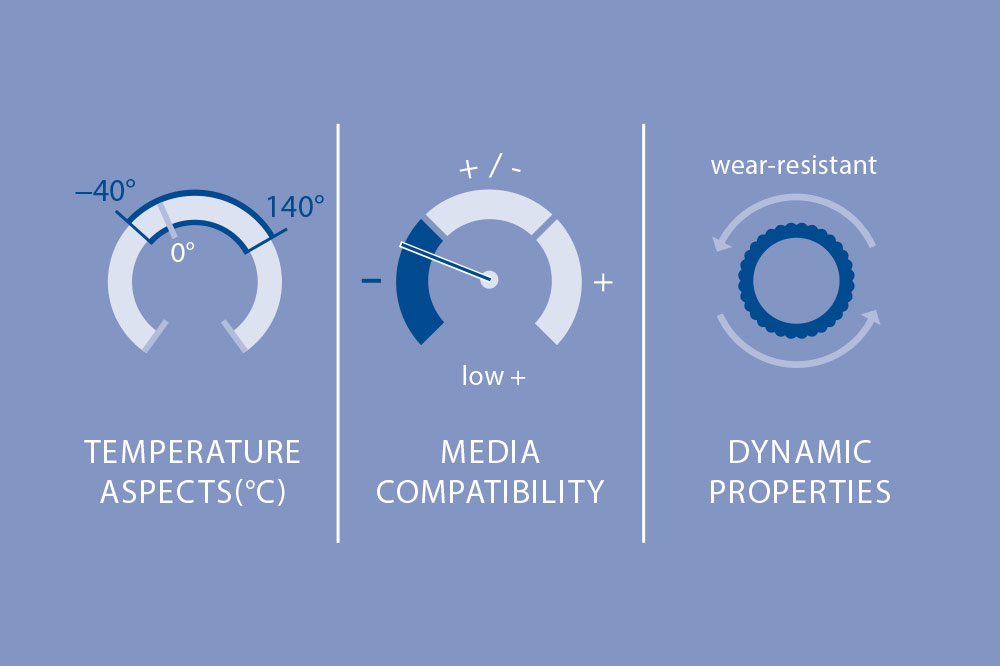

For example, HNBR is also resistant to hot water and exhibits good cold and high temperature behavior between –40 °C and 140 °C. In sealing technology, the significantly more expensive HNBR, which is a proven standard material for automotive engine timing belts, is primarily used in applications where higher temperatures and/or mechanical strength are required. Its strength is above all in demand for rod and piston seals, along with O-rings, radial shaft seal rings, boots and diaphragms. Especially in the processing industry, HNBR offers wide-ranging opportunities for use. In the process industry, for example, HNBR is superbly suited as a material for butterfly valve seals. HNBR is an excellent solution for dairies, the beverage industry and applications coming into contact with fatty media.

¹ The presence of R and not M as the last letter can be traced to the fact that most types of HNBR still contain a certain proportion of remaining double bonds. This also permits a representation of its molecular relationship to NBR.

² In chemical terms, hydrogenation is understood to mean the addition of hydrogen to other chemical elements or compounds.

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn!