Food & Beverage

Premium Seals for the Food & Beverage Industry

From Hygienic Design and Legal Compliances to the Prevention of Aroma Transfer and Media Resistance

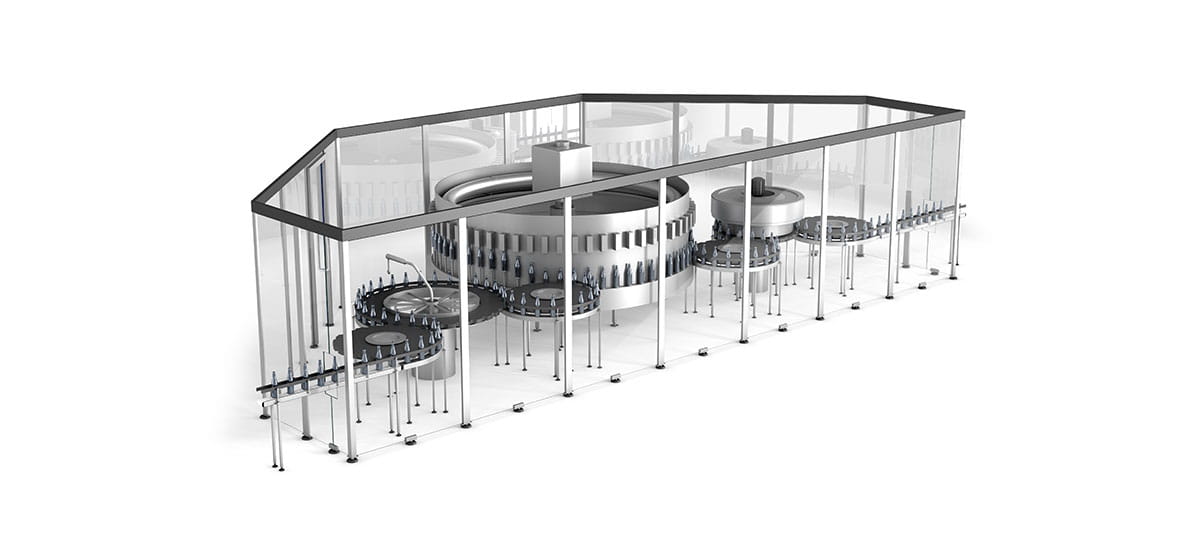

One of the biggest challenges in the food and beverage industry is the broad range of different end products and applications, such as filling machines, heat exchangers, valves and many more. These pose various requirements on the used sealing solutions. They not only have to withstand extreme temperatures, high pressures, greases, acids, abrasive media and CIP/SIP cleaning agents, but must also comply with the hygienic design standards as well as the relevant legal regulations, such as EG (Reg.) 1935/2004, FDA, 3-A® Sanitary Standards, GB 4806 and GB 9685. Additionally, the avoidance of aroma transfer plays an important role.

Application Examples

Related Products

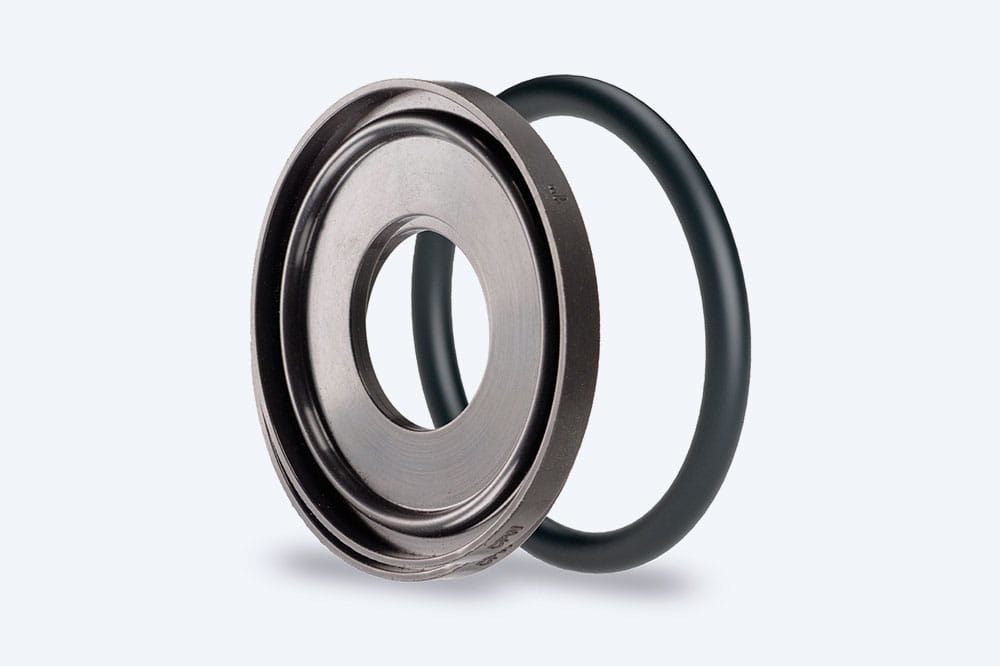

Radial Shaft Seals

The experts at Freudenberg Sealing Technologies develop special radial shaft seal designs that are tailored to the requirements of the food and beverage industry. Examples are the Radiamatic® HTS II, the Simmerring® BlueSeal or the Simmerring® B2PT. As the product media only come into direct contact with high-performance materials, such as PTFE and Fluoroprene® XP, they are well suited for use in aggressive media or with high temperatures. Some of them even meet the hygienic design standards.

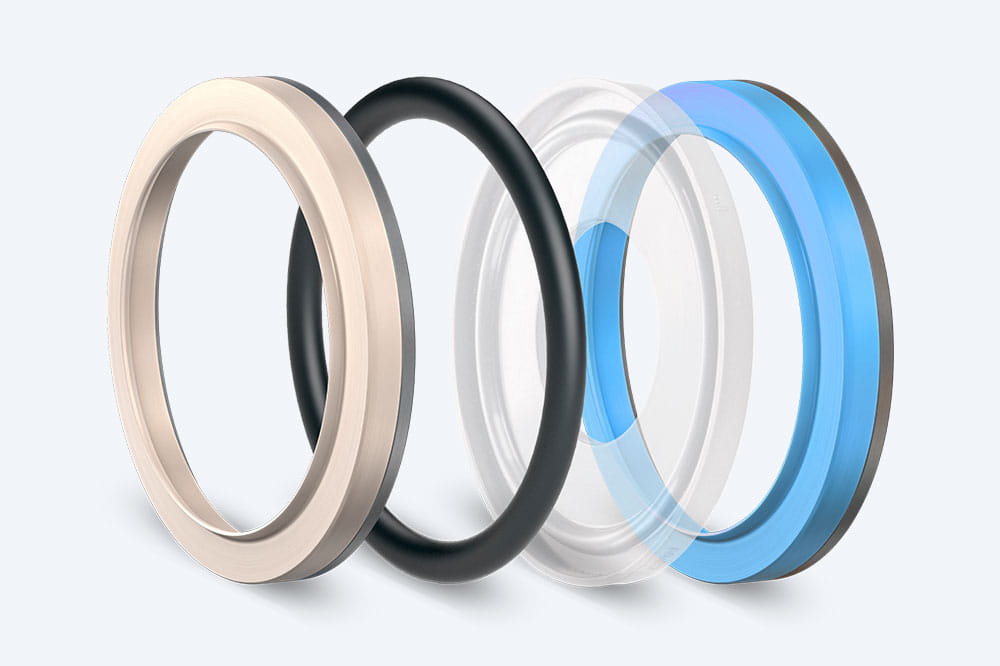

Clamp Seals

Clamp seals are the ideal sealing element for flange connections in continuously operated systems. The portfolio of Freudenberg Sealing Technologies includes standardized and close to norm clamp seals “made in Europe” that offer you an easy and safe pipe connection. They are available in five premium materials that comply with international legal regulations. Additionally, they are reusable after opening the connection, offer a very good elasticity, easy installation and many other advantages.

O-Rings

O-rings are used as universal sealing elements in almost all applications and offer an excellent price-performance ratio. At Freudenberg Sealing Technologies, O-rings can be manufactured in all elastomer materials, such as 70 EPDM 291, 75 Fluoroprene® XP 41 or 75 Simriz® 494. These have all relevant approvals for the food and beverage industry. In addition to round O-rings, oval, rectangular, semicircular and x-shaped cross-sections are also possible.

Hygienic Product Line

Freudenberg Sealing Technologies developed a unique product portfolio that is tailored to the high purity requirements of the process industry. This includes various sealing solutions, like for example the Hygienic Usit®, dead-space-free radial seals, the Radiamatic® HTS II 9539 VL or aseptic O-rings.

A special highlight is the Hygienic Pressure Seal made of a combination of Fluoroprene® XP or EPDM and PTFE Quantum® that prevents dead spaces thanks to a flat contact surface to the process medium.

Diaphragms

As flexible sealing elements diaphragms are used to regulate and switch with the help of pressure. In order to perfectly match the requirements of the food and beverage industry and to vary the diaphragm’s performance, Freudenberg Sealing Technologies is able to design customized diaphragms with fabric reinforcements, metal inserts, foil layers or other adaptions. The premium materials, such as 70 EPDM 291 or Fluoroprene® XP offer a very good media resistance as well as a long service life.

V-Seal Set Packings

V-seal set packings are suitable for use in different applications with translatory motion or slow rotational movement, such as parts of mixers or the spindles of regulation valves. The portfolio of Freudenberg Sealing Technologies covers all relevant applications and their requirements – from high temperatures and pressures to aggressive chemicals. V-seal set packings can either be standardized or customized and are a good alternative to stuffing box packings.

Highlight Materials

Fluoroelastomers for the Food and Beverage Industry

In order to preserve the unique taste of food and beverages, it is important to prevent aroma transfer. This occurs when different beverages or liquid foods pass through the same bottling line, one after the other. Freudenberg Sealing Technologies’ allrounder material Fluoroprene® XP solves the issue. It absorbs only a little fraction of the flavoring without releasing it and guarantees that foods and beverages retain their original flavor. Product examples are O-rings, customized parts, diaphragms, clamp seals, Hygienic Usit® rings and machined seals.

Another fluoroelastomer that is especially suitable for the food and beverage industry is 75 FKM 239961. It is peroxidic cross-linked, which complies with the latest regulations for sealing materials with direct product contact. It offers a very good media resistance and high purity. Freudenberg Sealing Technologies currently offers O-rings made of 75 FKM 239961. In the future customized solutions will also be possible.

EPDM as High-Performance Material for CIP/SIP Processes

EPDM (ethylene propylene diene rubber) can be used for almost all sealing products and is one of the most-used sealing materials in the food and beverage industry. Freudenberg Sealing Technologies’ premium EPDM family (60 EPDM 290, 70 EPDM 291 and 85 EPDM 292) is perfectly suitable for a wide range of O-rings, customized parts and diaphragms within the food and beverage production.

The materials perform especially well in CIP/SIP media. This was also proven with a benchmark study of 70 EPDM 291 compared to two competitor materials. Here it became clear that 70 EPDM 291 shows very good resistance to the CIP/SIP media and the associated demanding conditions (e.g. in steam up to 180°C/356°F).

At the same time the three materials are able to withstand different product media, from beer wort to fatty chocolate and various beverages. Additionally, they comply with the relevant legal regulations, like for example EG (Reg.) 1935/2004, FDA or 3-A® Sanitary Standards.

Food Conforming Materials for Global Use

Since 2016 China has its own legal requirements for the food and beverage industry that differ from the US and EU regulations. As both the migration tests and the approved raw materials are not the same, the complexity of finding a material for global use gets high. Freudenberg Sealing Technologies offers special sealing materials that comply not only with the new Chinese standards, GB 4806 and GB 9685, but also with other global regulations, such as FDA, EG (Reg.) 1935/2004 and EU (Reg.) 10/2011. This portfolio contains different EPDM variants, silicones, PTFE compounds, Polyamide and Polyethylene. The EPDM materials are available for O-rings and customized parts, the silicones are available as O-rings, diaphragms and customized parts and the plastics are available as support rings. Some of the materials can also be machined with our Freudenberg Xpress® service.

Services for the Process Industry

Virtual

Showroom

You can expect digital content,

such as 3D animations and virtual production tours,

as well as free webinars and a free whitepaper!

Related Documents

-

Sealing Solutions for Applications in the Beverage Industry

Due to the many different applications, there are a variety of challenges for seals in the beverage industry that need to be overcome.

-

Sealing Solutions for Drive Shafts in the Process Industry

Due to the many different and often unique features of the systems and processes in the pharmaceutical, food and chemical industries, a sealing system with drive shafts can be challenging.

-

Product Line for Hygienic Plants in the Process Industry

Freudenberg Sealing Technologies develops innovative sealing solutions with international industry-specific approvals, especially according to hygienic design standards. All products are resistant to the process medium itself and to all cleaning media used in CIP/SIP processes.

-

Material Portfolio for the Food and Beverage Industry

Freudenberg Sealing Technologies offers specially developed sealing solutions made of elastomer materials and technical plastics. These have all the necessary certifications and meet the conformity requirements relevant for applications in the food and beverage industry in the USA, Europe and China.

-

Clamp Seals for the Process Industry

Clamp seals make fast and secure flange connections in continuously operating equipment. Due to their symmetrical geometry, the clamp connections can be mounted and re-separated very easily.

-

Extractables EPDM-Benchmark

In food and pharmaceuticals industries production today, everything revolves around the issue of purity.

-

Hygienic Usit®

The Hygienic Usit® from Freudenberg was developed especially for the process industry and is setting completely new purity standards.

-

Food Conforming Materials for Global Use

Freudenberg Sealing Technologies offers engineering plastics specially tailored to the food industry, such as polyamides, PTFE and polyethylene.

-

Fluoroprene® XP - The premium all rounder for the process industry

A wide variety of applications that are impressive right down the line: Fluoroprene® XP is the universal sealing material for steam sterilization, aggressive CIP/SIP media and high-fat concentrations.

-

75 FKM 239961 – Peroxide Cross-Linked Fluoro Rubber

As a peroxide cross-linked material, the newly developed 75 FKM 239961 from Freudenberg Sealing Technologies meets the latest regulatory requirements for materials in the food industry with direct product contact.

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn!